Hot Work Safety Program

The Hot Work Safety Program establishes minimum requirements for performing hot work operations on university properties.

Scope

A hot work permit is required for any operation on UCF properties involving open flame or producing heat and\or sparks as defined by the Florida Fire Prevention Code. This work includes but is not limited to welding and allied processes (e.g., oxy-fuel gas welding, open-flame soldering, brazing, thermal spraying, oxygen cutting, arc cutting), grinding, thawing pipe, torch applied roofing, hot riveting, and heat treating. Hot work is not intended to include candles, pyrotechnics or special effects, cooking operations, electric soldering irons used in a safe manner, or the use of burners and similar standard laboratory equipment in approved laboratory spaces.

Responsibilities

Contractors

Before starting any hot work contractors shall verify they have obtained the necessary approvals from a permit authorizing individual (PAI) and/or Environmental Health and Safety (EHS) for the requested or designated location, and are in compliance with all aspects of this program. Contractors must have an established company hot work program available for review upon request. A copy of the contractor’s company Hot Work Permit signed by their PAI for each specific scope of work is required to be submitted with their UCF Hot Work Permit request. Contractors are required to verify proper Florida Building Code permits are in place when appropriate for the work scope.

Departments

Departments requesting or performing hot work whether, by internal staff, students, or hired contractor are responsible for ensuring safe operations. Departments with ongoing operations shall establish an approved hot work program plan and designate a PAI to coordinate and oversee permitted activities and ensure that operators are provided with adequate training for the work task they are assigned.

Environmental Health and Safety (EHS)

EHS has the responsibility for assisting departments in developing appropriate hot work safety plans and providing technical guidance by:

- Working with PAI’s to develop departmental programs.

- Training PAI’s in permit review and authorization.

- Issuing Designated Area permits for fixed research and shop locations.

- Reviewing permits for incidental entities that do not fall under a designated PAI’s.

- Reviewing programs on a periodic basis for continued compliance.

- Providing oversight in accordance with applicable codes and standards, and where necessary has the responsibility and authority to halt any unsafe practices.

- Assisting with employee training on hot work and fire safety. (EHS provided general safety review training, not the actual skills needed for hot work processes or technical equipment use.)

Hot Work Operator (HWO)

The hot work operator shall have adequate training on the operations to be performed and ensure process safety by:

- Completely and accurately filling out the Hot Work Permit Request.

- Obtaining a permit and PAI approval.

- Examining all equipment for safe operating condition and proceed only if all required protective equipment is on-site and in usable condition.

- Executing work in accordance with the approved permit and ceasing work if unsafe conditions develop or the environmental parameters differ from the approved project scope.

Permit Authorizing Individual (PAI)

The PAI is responsible for the safe operations of hot work activity under their supervision. These duties include but are not limited to:

- Being familiar with the hot work processes utilized by their department.

- Supervising the hot work operators and verifying they are adequately trained and provided with the appropriate protective equipment.

- Reviewing the hot work process and location prior to each work start to determine the site-specific hazards, equipment, and safety features required are present and in usable conditions.

- Completing the PAI checklist to approve and issue hot work permits to hot work operators.

- Providing EHS a copy of all permits issued, and notifying EH&S and facilities operation prior to the start of work.

- Verifying appropriate Florida Building Code permits are in a place where appropriate for the work scope.

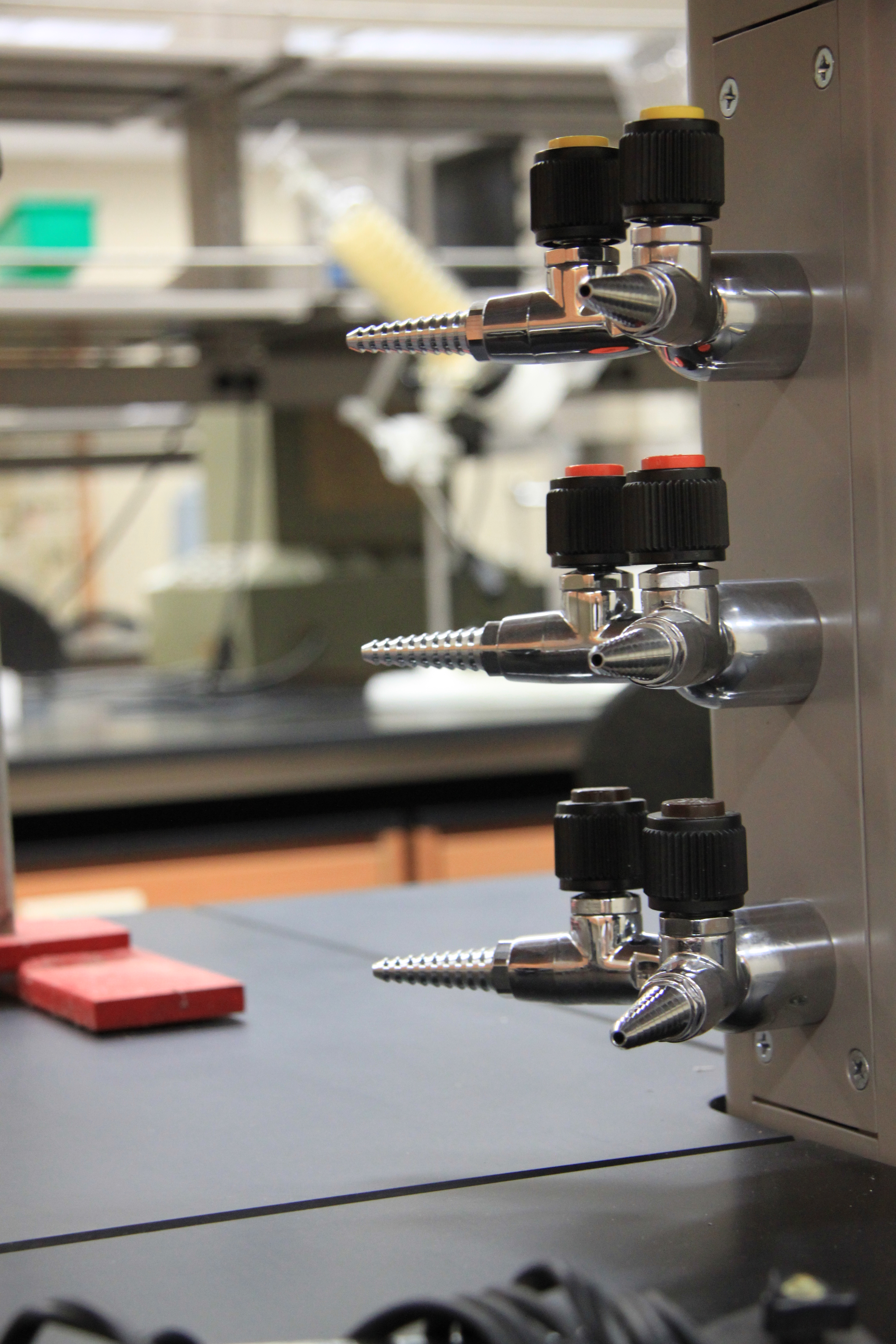

- Ensuring that only approved apparatus, such as torches, manifolds, regulators and pressure reducing valves, are used.

- Determining that fire protection and extinguishing equipment are properly located and readily available.

- Ensuring sufficient local exhaust ventilation is provided to prevent the accumulation of any smoke and fume.

- Ensuring the designated fire watch personnel are staffed.

- Verifying Facilities Operation has been adequately notified for coordination.

Hot Work Request Procedure

Departments will establish PAI’s to coordinate with EHS in establishing an approved department hot work program. PAI’s will oversee the hot work permit process for the staff, students, and contractors under their supervision in accordance with their approved program. The department is required to coordinate all necessary hot work fire watch personnel for the duration of the hot work.

Departments requesting Designated Area (DA) permits will contact EHS for program review and approval. A Designated Area is a fixed shop or research type space where repetitive hot work is planned to be conducted in a consistent manner. An annual permit will be issued once the program is approved and all required safety training is complete.

A procedure manual shall be submitted to EHS by the Department requesting hot work. Designated Areas must maintain an updated copy at the DA location including a list of approved operators to conduct work under the supervision of the PAI. The procedure will need to address the items listed here at a minimum:

- Designated PAI (Note: In research areas the Principal Investigator (PI) is responsible for all activities under their supervision. A PI may delegate a PAI.)

- Policies and Procedures Specific to the Department’s Operations

- Authorized Users and HWO’s

- Fire Watch Procedures

- Fire Prevention Equipment

- Hot Works Equipment Manual’s

- Equipment Maintenance

- Personal Protective Equipment Specific to Each Operation

- SDS’s (formerly MSDS’s)

- Approved Annual Permit for Designated Areas

- Fire Safety Training Requirements and Records

- Instructions to Contractors Covered by the Program

HWO’s shall fill out and obtain approval for the permit request from the applicable PAI or EHS in accordance with this program. All precautions as required by the Florid Fire Prevention Code, NFPA 51B and ANSI Z49.1 must be met or the hot work is not approved. Each department plan will outline the additional minimum notice required by their PAI. For EHS reviews, HWO’s must completely fill out and submit a Hot Work Permit Request Form five (5) workdays prior to the start of work to ensure adequate processing time. Emergency work will be handled on a case by case basis. Incomplete requests will not be approved. Contractors may submit their company hot work program to EH&S in advance for review and archiving to help expedite future requests.

Planned work requiring alarm or suppression system bypass and associated fire watch requires a minimum of 10 days’ notice to Facilities Operations (FO). Coordinate work through FO work control (407) 823-5223 and or your project manager; a work order may be required. Accidental alarm or suppression activation and subsequent consequences are the responsibility of the hot work operator\requester.

The PAI will review each request, inspect the site and equipment prior to the start of work in accordance with the checklist, and approve the request noting any special conditions. If upon the time of work the HWO does not have the required or adequate equipment, the permit is null and void and the work not approved.

Periodic program review will be executed by EHS to ensure continued compliance for all departmental programs and designated locations.

References

Florida Fire Prevention Code 6th Edition

NFPA 51B

OSHA 1910.252

ANSI Z49.1

Resources

Hot Work Permit Request (with PAI Checklist)

Fire Safety Contacts

Sharon Tinny

Fire Safety Specialist

Sharon.Tinny@ucf.edu

(407) 823-0324